We produce big variety of steel products all custom built according to our customers design and needs.

Biggest part of our production is production of pressure vessels with maximum pressure of 110 bar and minimum working temperature of -40 degrees.

Production of new crane wheels and reparation of used wheels.

We produce custom and specialized lifting hooks for industrial production.

We produce several types of valve protection caps, different types offer different design and uses for caps.

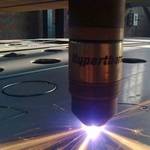

Our CNC cutting machine is dual mode plasma and oxi. Working table dimensions are 6x2m and maximal material thickness is 130mm.

We employ welders with many years of experience and they are all certificated to perform MIG/MAG welding for pressure vessels.

In pressure vessels production process our certified TIG welders provide necessary quality that is required for such products.

We have three automated SAW welding machines on which our certified welders perform welding for pressure vessels and other specialized parts.

On our CNC turning machine we are able to perform precise machining combined with speed of CNC machine.

We are able to perform cold forming of many different types, rolling, bending, forming, punching and more.

Our painting chamber is allowing us to create perfect conditions, such as temperature and airflow, that will guarantee quality painting.

Our products are sandblasted to ensure best preparation for any kind of anti corrosion protection.

Beograd

Headquarters

location_on Address - Čuburska 9/L2, 11000 Beograd, Srbija

phone Phone - +381 (0)11 407 4196

email Email - office@emdipproteam.co.rs

important_devices Web - www.emdipproteam.co.rs

Smederevo

Production plant

location_on Address - Šalinačka bb, 11300 Smederevo, Srbija

phone Phone - +381 (0)26 642 180

email Email - office@emdipproteam.co.rs

important_devices Web - www.emdipproteam.co.rs

© Em Dip pro team 2005-2017 All rights reserved.